Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

Free shipping on all orders

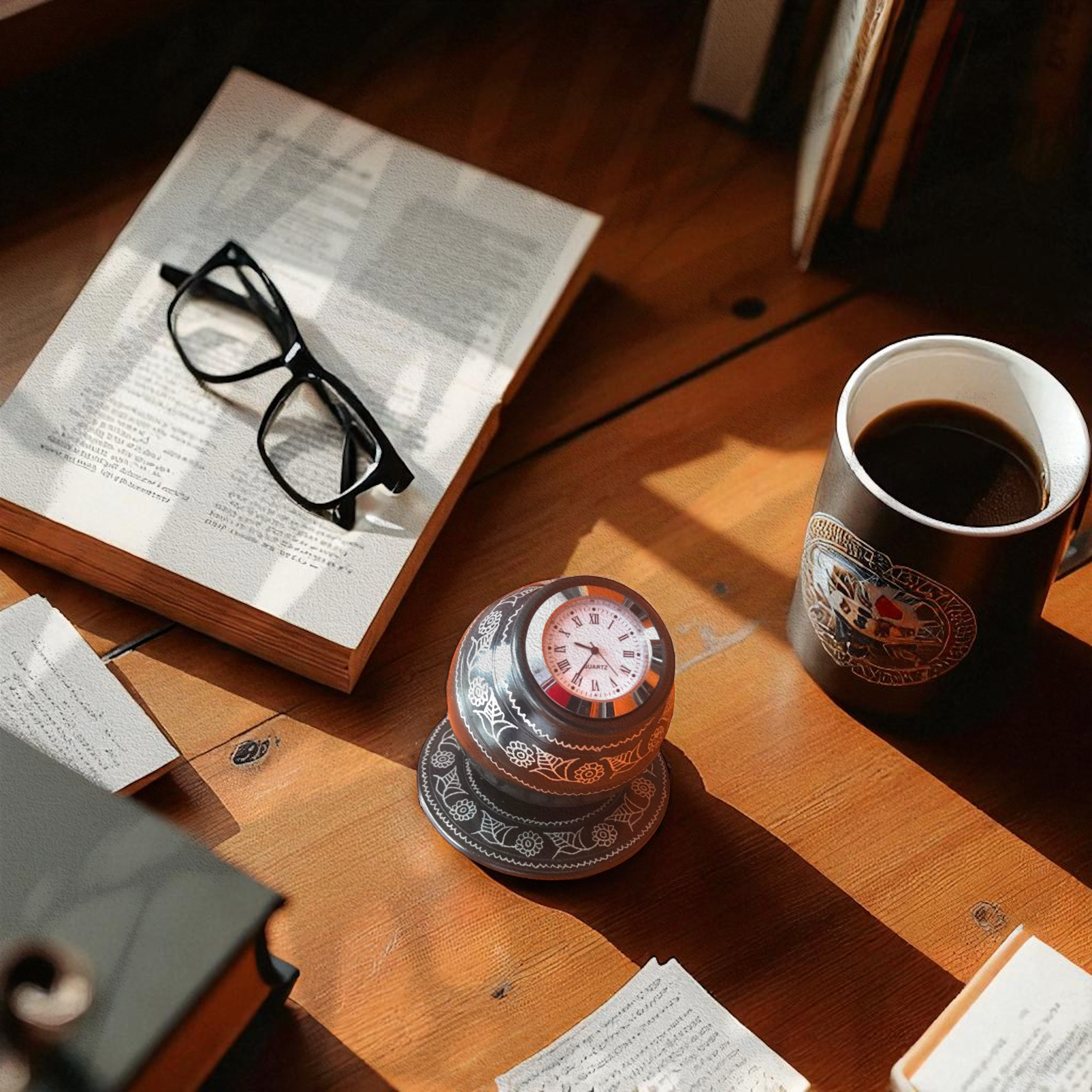

Our Featured Products

Why Mittiartisans?

Clay Prep

Before any form takes shape, the clay must be prepared with care. Natural riverbed clay is soaked, sieved to remove impurities, and then kneaded thoroughly in a process called wedging. This step removes air bubbles and ensures a smooth, even texture — like a workout that gets the clay ready to respond to the artisan’s hands.

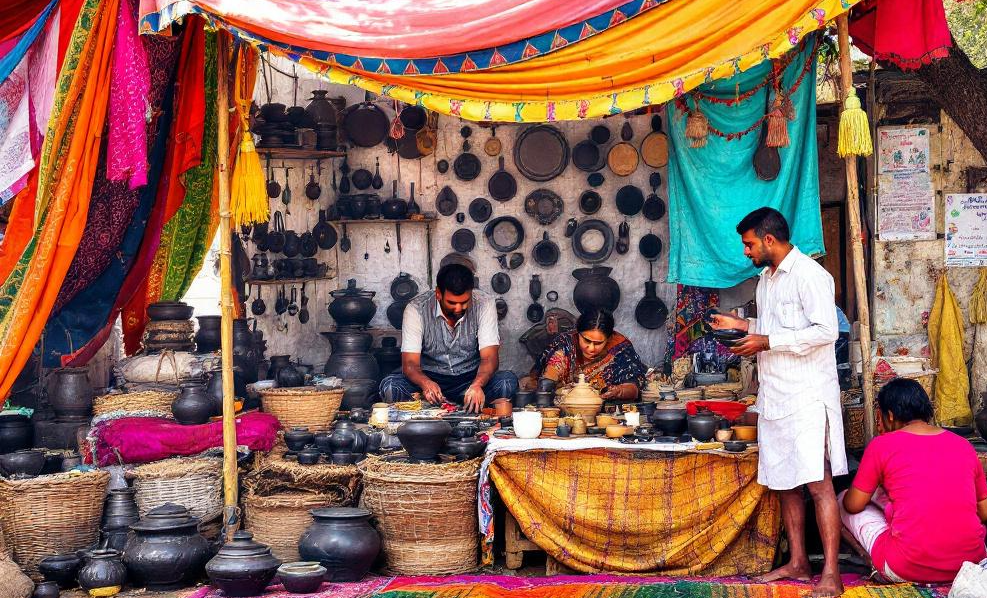

Pottery wheel shaping

This is where the magic begins. The clay is placed on the potter’s wheel — where every curve, edge, and surface is formed entirely by hand. There are no molds, no mechanical shortcuts. Just skilled hands, practiced over generations, guiding the clay into form through instinct and touch. Each piece is shaped individually, making no two exactly alike.

Firing in the Kiln

After shaping and drying, each piece is fired in a kiln, where earth and flame come together to harden the clay.

Black pottery undergoes a traditional smoke-firing ritual that infuses the clay with a deep, rich black hue and a unique, textured finish — a true gift from earth and smoke.

Terracotta creations are kiln-fired to gain strength and lasting durability.

Engraving & Finishing

Some pieces are hand-engraved with liquid silver, a hallmark of black pottery craftsmanship, adding intricate detail and a shimmering contrast to the deep black surface; others are left raw to highlight the natural form and texture of the clay. Finishing typically includes surface treatments such as sanding for smoothness and sometimes sealing with oil to protect and enhance the texture.